| |

|

|

|

|

|

|

|

|

| AKALI Glass Nano Coating |

|

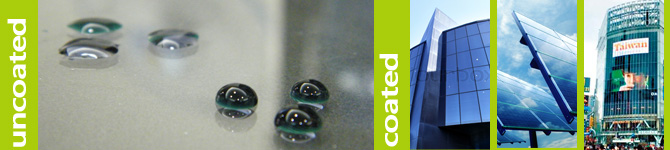

Hydrophobic and oleophobic properties � |

|

Protects surface from environmental corrosion & abrasion |

|

Abrasion and UV resistant |

|

Easy coating and re-coating process |

|

Highly durable – up to 5 years |

|

|

|

| |

|

|

|

|

| |

|

|

|

|

|

|

|

|

The Nano-coating protects smooth and glass-like surfaces from dirt, oil, limescale and other environmental contaminants. The main ingredient consists of inorganic Nano SiO2 particles (also called liquid glass) which bonds chemically with glass substrate. Treated glass is equipped with a colorless, vapor-permeable and ultra-thin nanofilm (with a thickness of less than a hundred nanometer). The coating possesses superior lotus effects and is water-repellent, anti-fouling and easy to clean, saving money on cleaning agents. Also, the product provides lasting protection and resistance against wear, chemicals, heat and UV light.

|

|

| |

Hydrophobic and oleophobic properties �

Non-stick and easy to clean– Minimized cleaning

Prevents streak marks, dirt build-up and algae formation

Protects surface from environmental corrosion, abrasion and contaminants

Completely colorless so no visible effects on the substrate

Heat resistant

Chemical resistant (pH-value of 13)

Abrasion and UV resistant.

Easy coating and re-coating process (hardens at room temperature. No additional energy or UV light required)�

Highly durable – up to 5 years in most conditions

Green and eco-friendly

|

|

| |

Automotive glass, solar panels, glass surfaces in sanitary areas (showers and mirrors), glazed ceramic surfaces (toilets, sinks and glazed tiles), glass panels of buildings and display glass

|

|

| |

Manually:

1.Spray evenly on the surface and wait for a few minutes (until dry)

2.Clean the surface in a circular motion with a clean microfiber or linen cloth

Industrially : By spray coating systems or polish coating systems

Coverage Rate

Manually : 120 – 160 m2 (sqm), Industrially : 80 - 100 m2 (sqm)

|

| |

|

| |

|